How Epoxy Table Top

Choosing the right materials

When it comes to creating a stunning epoxy table top, choosing the right materials is key. Make sure to select a high-quality epoxy resin that is specifically designed for creating table tops. You will also need a wooden table top, pigment powders or liquid dyes for coloring, mixing cups, stirring sticks, a heat gun or torch for removing bubbles, and sandpaper for finishing.

Preparing the surface

Before applying the epoxy resin, it is important to prepare the surface of the wooden table top. Sand the surface to remove any existing finish and create a smooth and even surface. Clean the table top thoroughly to remove any dust or debris that could affect the final result.

Mixing and pouring the epoxy

Once the surface is prepared, it’s time to mix the epoxy resin according to the manufacturer’s instructions. Make sure to mix thoroughly to ensure that the resin cures properly. Pour the mixed epoxy onto the table top and use a spreader or brush to evenly coat the surface. Use the heat gun or torch to remove any bubbles that may have formed.

Creating a stunning design

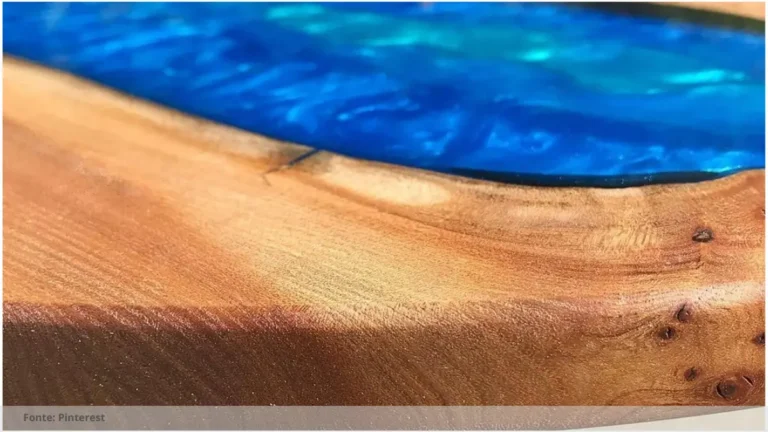

This is where you can let your creativity shine! Add pigment powders or liquid dyes to the epoxy resin to create a unique and stunning design. Use a brush or stirring stick to swirl the colors together for a marbled effect, or pour multiple layers of different colors for a more intricate design.

Creating a stunning epoxy table top can seem daunting at first, but with the right materials and techniques, you can achieve truly stunning results. By following this step-by-step guide, you can create a one-of-a-kind table top that will be the envy of all your friends and family.

Read the Recent Articles of the Day by Clicking Here!

If you want to achieve stunning results when creating an epoxy table top, it is important to follow a step-by-step guide carefully. Here are some important suggestions to keep in mind:

1. Prepare the surface: Before you start applying the epoxy resin, make sure the surface of the table top is clean, smooth, and free of any dust or debris. Sand down any rough areas and wipe the surface clean with a damp cloth.

2. Measure accurately: It is crucial to measure the amount of epoxy resin and hardener accurately. Follow the manufacturer’s instructions on the ratio of resin to hardener to ensure the mixture cures properly.

3. Mix thoroughly: Thoroughly mix the epoxy resin and hardener together for at least 3-5 minutes to ensure they are fully combined. This will help prevent any soft spots or uneven curing.

4. Pour evenly: Slowly pour the mixed epoxy resin onto the table top in a smooth and even manner. Use a spreader or brush to help distribute the resin evenly across the surface.

5. Remove air bubbles: To prevent air bubbles from forming in the epoxy, use a heat gun or torch to quickly pass over the surface. This will help release any trapped air bubbles and create a smooth finish.

6. Let it cure: Allow the epoxy table top to cure in a clean and dust-free environment for the recommended amount of time specified by the manufacturer. Avoid touching or moving the table top during this time to prevent any imperfections from forming.

7. Sand and finish: Once the epoxy has fully cured, sand down any rough edges or imperfections with fine-grit sandpaper. Apply a coat of clear sealant or finish to protect the epoxy and enhance its glossiness.

By following these suggestions, you can create a stunning epoxy table top that is smooth, durable, and visually appealing. It is important to take your time and pay attention to detail during each step of the process to achieve the best results possible.

Frequently Asked Questions: How epoxy table top

What materials are needed to make an epoxy table top?

To make an epoxy table top, you will need epoxy resin, hardener, a mixing container, a mixing stick, a heat gun or torch, a sander, and the table surface.

How do you properly prepare the surface for epoxy pouring?

To properly prepare the surface for epoxy pouring, you should clean the surface thoroughly to remove any dust, dirt, or debris, and then lightly sand to ensure adhesion.

What are common mistakes to avoid in epoxy table making?

Common mistakes to avoid in epoxy table making include not properly preparing the surface, adding too much or too little epoxy, failing to mix thoroughly, and not allowing for proper curing time.

How long does it take for epoxy to fully cure?

The cure time for epoxy can vary depending on the specific product and environmental conditions, but typically it takes about 24 to 72 hours for epoxy to fully cure.

So, what do you think about this subject? Share your opinion in the comments and let’s continue discussing together!