Resin Epoxy Chemical: Everything You Need to Know for Optimal Applications

What is Resin Epoxy Chemical?

Resin epoxy chemical is a type of adhesive substance that is made up of resin and hardener components. When these two components are mixed together in the right proportions, a chemical reaction occurs, resulting in a durable and strong bond. Resin epoxy chemical is commonly used in various industries such as construction, automotive, and manufacturing for its excellent adhesive properties.

The Components of Resin Epoxy Chemical

Resin epoxy chemical is typically composed of two main components – resin and hardener. The resin component is typically a viscous liquid that provides the adhesive properties, while the hardener component is a catalyst that initiates the chemical reaction when mixed with the resin. It is important to carefully measure and mix these components in the correct proportions to ensure optimal bonding strength.

Applications of Resin Epoxy Chemical

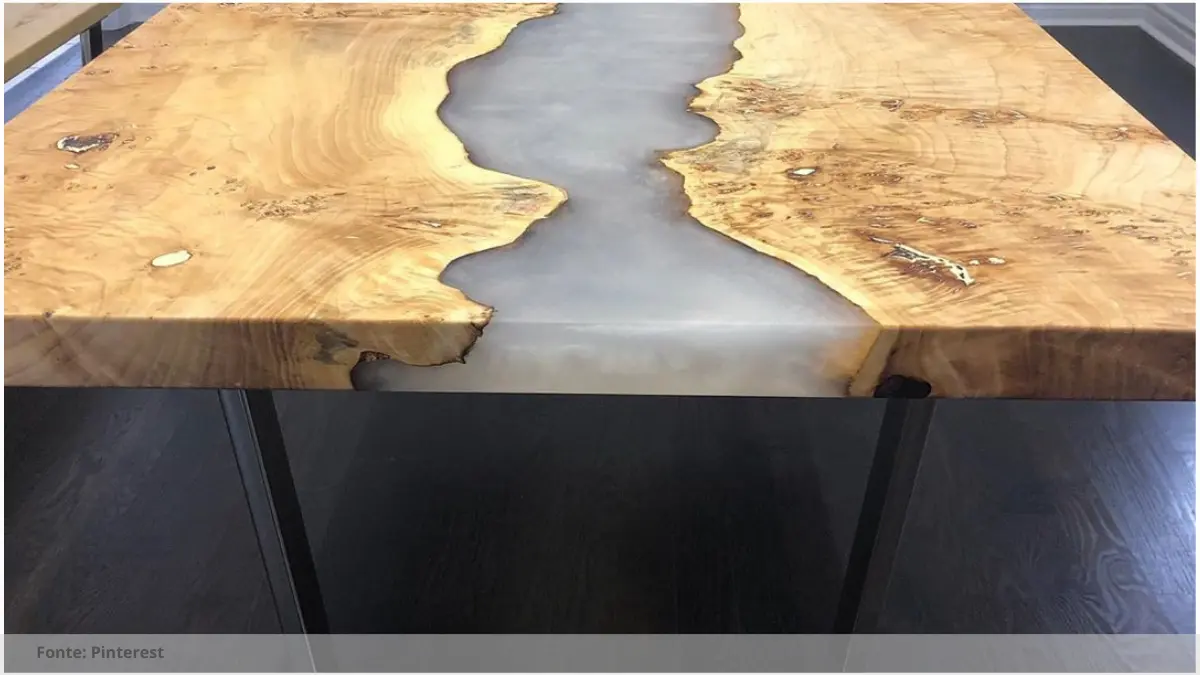

Resin epoxy chemical is a versatile adhesive that can be used for a wide range of applications. It is commonly used in construction for bonding materials such as metal, concrete, and wood. In the automotive industry, resin epoxy chemical is used for repairing cracks and chips in vehicle parts. It is also used in manufacturing for creating strong and durable bonds between different materials.

Tips for Using Resin Epoxy Chemical

When using resin epoxy chemical for your applications, there are a few key tips to keep in mind. Firstly, make sure to carefully read and follow the manufacturer’s instructions for mixing and applying the adhesive. Additionally, ensure that the surfaces to be bonded are clean, dry, and free of any contaminants that may interfere with the bonding process. Finally, allow sufficient time for the adhesive to cure and set before applying any stress or load to the bonded materials.

In conclusion, resin epoxy chemical is a versatile and effective adhesive that is commonly used in various industries for its excellent bonding properties. By understanding the components of resin epoxy chemical, its applications, and following key tips for optimal use, you can ensure successful bonding for your projects.

Read the Recent Articles of the Day by Clicking Here!

One important suggestion when working with resin epoxy chemicals is to always follow the manufacturer’s instructions carefully. This includes ensuring you have the correct ratio of resin to hardener, using the recommended mixing tools and techniques, and understanding the proper temperature and humidity conditions for optimal curing.

Additionally, make sure to wear the appropriate personal protective equipment, such as gloves, goggles, and a respirator, to protect yourself from harmful fumes and skin irritation.

It is also important to properly prepare the surface you will be applying the resin to, by cleaning and sanding it as needed to ensure proper adhesion.

Lastly, take your time and work in a well-ventilated area to avoid inhaling fumes. Rushing the application process can lead to mistakes and a subpar finish. By following these suggestions, you can achieve successful and long-lasting results with resin epoxy chemicals.

Frequently Asked Questions: Resin epoxy chemical

What is resin epoxy chemical used for in industrial applications?

Resin epoxy chemicals are commonly used in industrial applications for adhesives, coatings, sealants, and composite materials due to their strong bonding properties and resistance to heat and chemicals.

How does resin epoxy compare to other adhesive options available?

Resin epoxy provides a durable and strong bond that is resistant to temperature, water, and most chemicals, making it a superior adhesive option compared to many others.

What are the key benefits of using resin epoxy in construction?

Resin epoxy in construction provides a strong, durable, and versatile adhesive that is resistant to heat, water, and chemicals, making it ideal for bonding various materials together securely.

Are there any safety precautions to keep in mind with resin epoxy?

When working with resin epoxy, it is important to wear protective gloves, goggles, and a mask to prevent skin irritation and inhalation of fumes. Ensure adequate ventilation in workspace.

So, what do you think about this subject? Share your opinion in the comments and let’s continue discussing together!